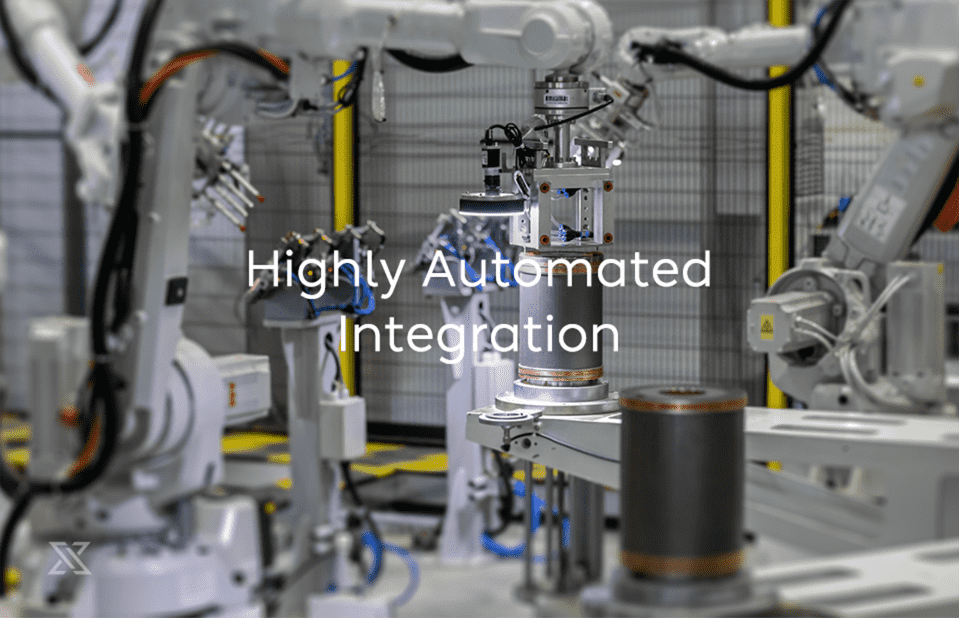

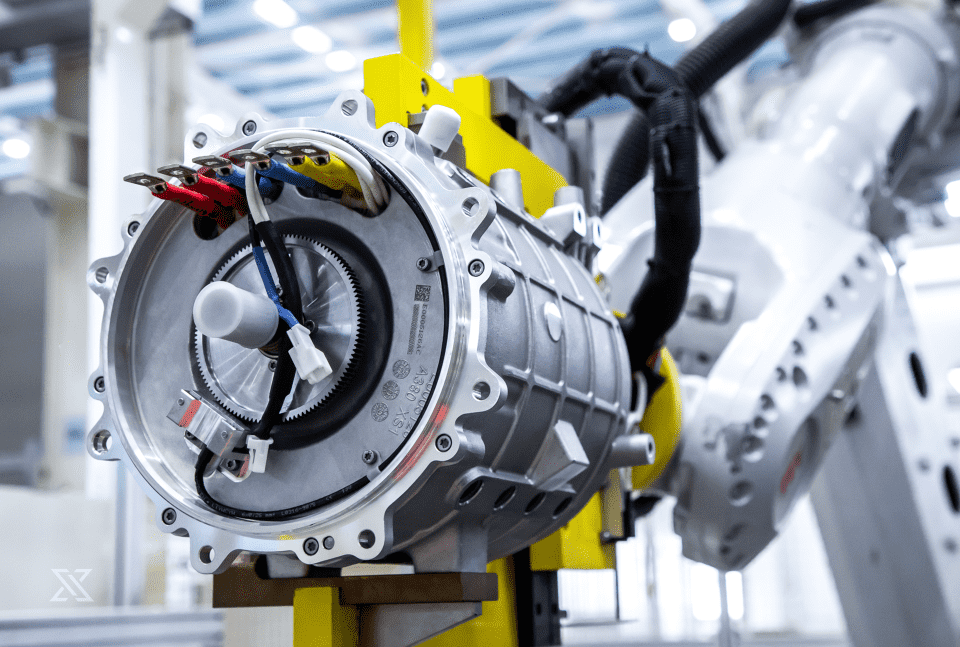

To meet demands from different clients,XPT leverages its manufacturing capabilities, maximizes systematic efficiency, synergizes highly automated integration with top-notch manufacturing. XPT spearheads the way of independent research, development and manufacturing of necessary EV components, offering eco-friendly, efficient and reliable next generation propulsion transportation solutions to OEMs.

XPT Advance Manufacturing Transforms Splendid Visions and Prospects into Reality

Electric Drive System (EDS) Production Lines, Power Electronic Unit (PEU) Production Lines, and Energy Storage System (ESS) Production Lines-Nanjing

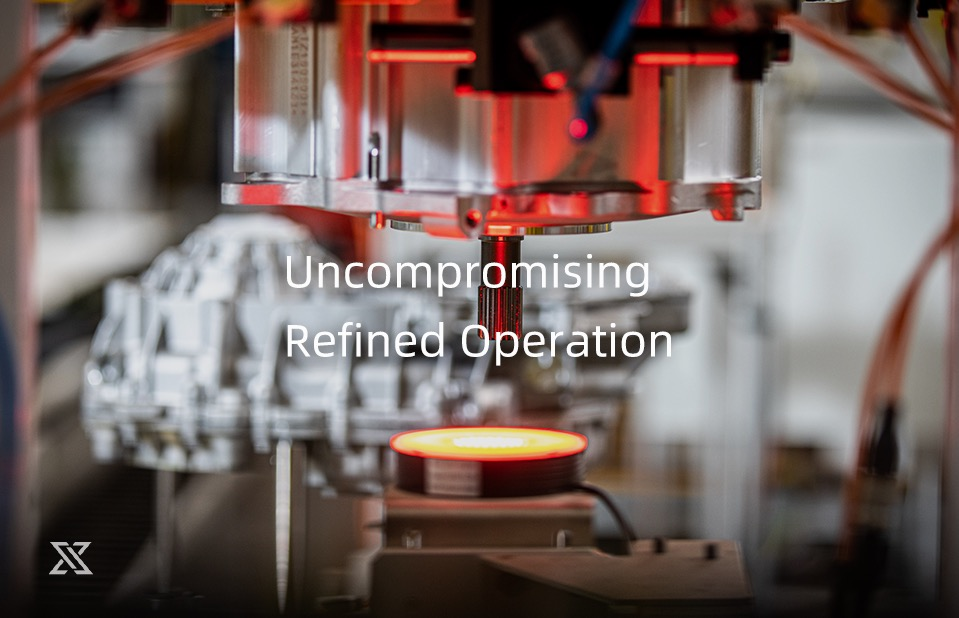

Located in Nanjing Economic and Technological Development Zone, XPT Nanjing covers a floor space of 528 mu, and owns Electric Drive System (EDS) production lines with an annual capacity of 300,000 sets, Power Electronic Unit (PEU) production lines, and Energy Storage System (ESS) production lines. It is one of large-scale manufacturing bases of core components for new energy vehicles in the world. The manufacturing base has highly flexible and automatic production lines, adopts many world-leading technologies such as integrated winding and embedding technology, laser welding, turnery and dynamic balance, traces raw materials and processes 100% through a deep application of the MES system, and guarantees consistent product quality and creates high-performance core components based on advanced production technology and transparent production.

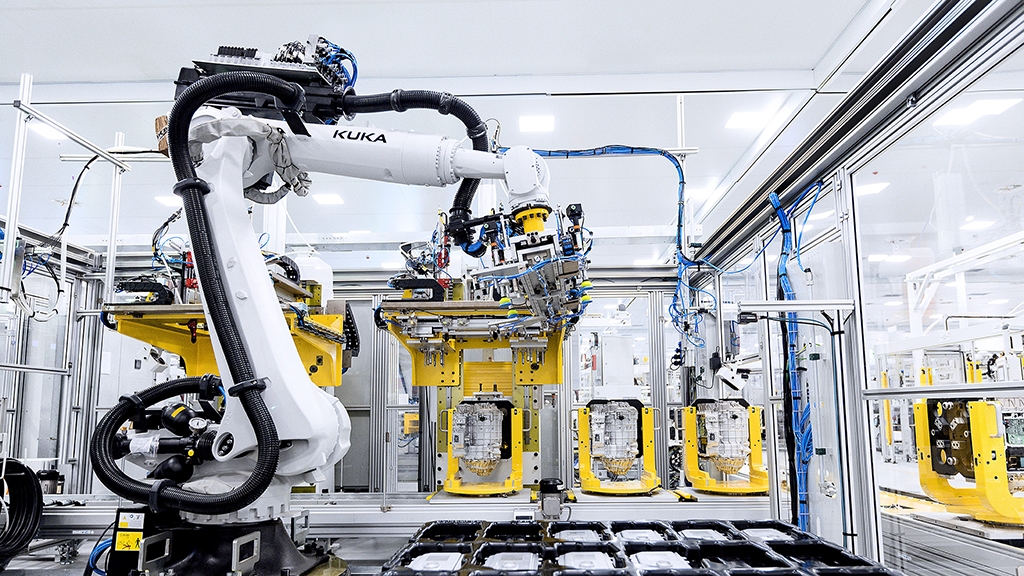

EDS (Electric Drive System) Production Lines & Power Electronic Unit (PEU) Production Lines - Hefei

Located in Hefei NeoPark, XPT Hefei covers a floor space of 43,500 square meters and has a planned annual capacity of 1,300,000 pc/650,000 sets. Adopting technological and industrial leading automation equipment, the production lines of XPT Hefei are characterized by high automation, intelligence, fast pace, flexibility and leanness. The overall automation rate of the production lines is above 80%. Equipped with industrial leading digital intelligent systems, and covering the whole process involving supply chain logistics, technology development, production & operation and quality control, it has realized a digital and intelligent closed-loop operation of EDS products upstream and downstream.