聚焦2020北京车展,XPT为高端电动汽车提供双电机解决方案

2020-10-21

2020北京车展刚刚落下帷幕,据统计,在本届北京车展上亮相或者上市的新车中,近40%左右的车型为新能源车型。而XPT蔚来驱动科技作为新能源汽车制造行业的领军者,首席执行官曾澍湘先生作为北京车展SAE论坛主办方特邀的演讲嘉宾,在此次论坛上向大家分享了永磁+感应双电机的高端电动汽车动力总成方案,让更多人从“蔚来汽车”认识到“XPT蔚来驱动科技”。

XPT 蔚来驱动科技,是蔚来集团的控股公司,成立于 2015 年,如今已经逐渐发展为一家独立的企业,总部位于江苏南京,坚持以用户为中心,打造电动化、智能化、轻量化的平台,用科技升级人类的出行方式。自成立以来,XPT一直致力于成为驱动全球科技出行品牌,为客户提供更环保、更高效、更安全的智能动力解决方案,从而推动新能源及电动汽车的商业化与发展。

「能不能比特斯拉快 0.1 秒」曾澍湘表示 ,XPT诞生之初直接对标的就是行业巨头特斯拉。为了达成当时立下的百公里加速4.4秒的目标,XPT遍寻市场中所有可能的电机合作伙伴无果,最终走上自主研发的道路。

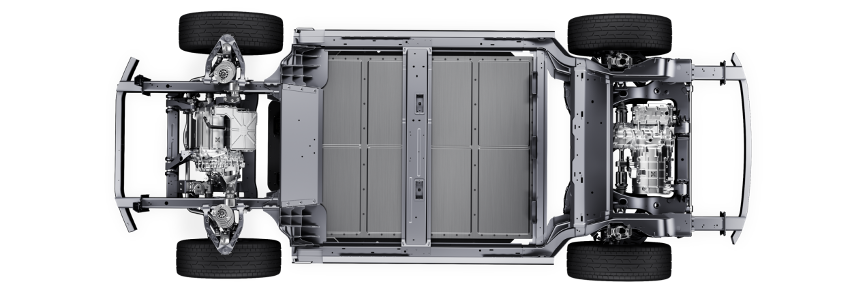

2017年,首台搭载XPT自主研发的电驱动总成,整备自重2.46吨,百公里加速突破4.4秒的蔚来ES8正式投入国内市场,而如今,XPT自主研发的产品供应链已经包含了EDS 电驱动系统及相应的核心部件如永磁电机、感应电机、减速箱和电机控制器,涵盖电动汽车所需的核心零部件,XPT在全球范围内都拥有强大的正向研发系统能力及资源匹配。

顶级工艺、高智能化、高自动化、先进制造是曾澍湘对于XPT位于南京的先进制造工厂的总结,工厂建成 3 年之后,XPT在 2019 年交付了 40408 台大功率(大于150KW)三合一 EDS 电驱动单元,位列全国第一。而今年仅 1-8 月,EDS 交付量就已经达到了 44830 台,是名副其实的高性能电驱动系统市场领先者。

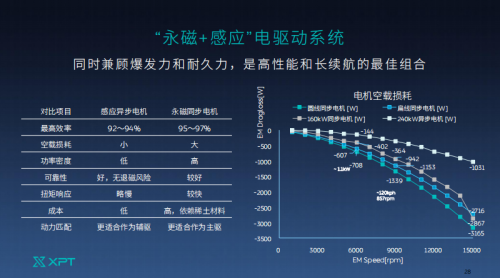

高端电动汽车的最佳组合:“永磁+感应 ”双电机

此次论坛中,也谈及了前段时间在业内引起热议的“单电机就是耍流氓”,曾澍湘再次针对此解释道,在当下的技术条件中,永磁+感应双电机应该是高端电动车的核心配置,因为永磁电机和感应电机可以做到优势互补。

XPT 的 240KW 异步感应电机,是中国唯一的大功率异步电机三合一系统,它拥有全球首个双三相拓扑逆变器、国内首个量产铜转子技术,15000 转高性能减速器等等极具前瞻性的动力技术,保证了强大稳定的动力输出。搭配国内首个批产使用定子扁导线技术的160KW永磁同步电机,拥有轻量化的设计,齿轮双面修形,行业内唯一支持正反转减速箱等等,带来了更加持久的续航表现。

相比于多数企业的双永磁电机,XPT采用的永磁+感应双电机方案没有拖拽效应,续航也会更长。双电机的搭配可以做到同时兼顾爆发力和耐久力,是今天可见技术上高端电动汽车获得高性能和长续航的最佳组合。

双电机的存在,不仅比单电机拥有更高的性能,同样也更具备安全性。两个电机也是一种“备用”关系,毕竟两个电机失效的概率远低于一个电机,一套电机万一在路上发生故障,另一套依旧还能支撑正常行驶。就像蔚来汽车总裁秦力洪之前说过的「蔚来从来没有发生过车子因为两个电机都坏了停在路上的事情,一个电机坏了试过,但另一个电机还可以让你开到安全的地方停下来。」

目前,XPT的年产能已经达到30万台,从工厂内部看还有将近一半的剩余空间可以供后续产能扩充使用,也就意味着其最大年产能有望超过60万台。曾澍湘表示,除了专供蔚来汽车之外,XPT也在对全球开放这两款电机产品。相关信息透露,已经有海外意向客户有意签单,产品主要集中在需要强动力输出的电动车型,而这也将带动中国制造的升级。